viscous products

Home > Industrial filters > PLM Self cleaning filter

Automatic self-cleaning filter for viscous products

The PLM automatic self-cleaning scraper filter is an industrial filter fabricated in stainless steel equipped with a scraper, that does not use any consumables. It is ideal for filtering high viscosity industrial liquids, such as painting, as well as for the chemical, cosmetic or food industries.

The PLM filter is self-cleaning and automatic. It has an incredible ability to filter high viscosity products (up to 200,000 cPs). Designed and manufactured in France, this self-cleaning filter is simple, solid and efficient.

This industrial self-cleaning filter does not require any consumables, such as filter bags or filter cartridges and is fully automated. It is particularly suitable for industrial filtration of water-based or solvent-based paints and processes for the food industry, such as dough or pastry, jams, chocolate or any other viscous product.

The pharmaceutical and cosmetic industries particularly appreciate the ability to perform “clean-in-place” cleaning for the filtration of active ingredients, cosmetic creams or lotions.

The performance of the PLM self-cleaning scraper filter

The performance of the PLM self-cleaning scraper filter depends on the flow rate and viscosities of the products to be filtered. This type of filter can also process large flow rates in duplex or triplex systems.

The PLM self-cleaning filter was designed for the filtration of high viscosity products. Viscous products usually tend to pose a real problem for bag filters, disc filters, propeller filters, etc. This is not the case for the PLM self-cleaning filter, which can easily perform high viscosity filtration for products up to 200,000 cPs.

from 25 microns to 2000 microns

up to 200 000 cP

up to 35 m3/h per unit

zero consumables

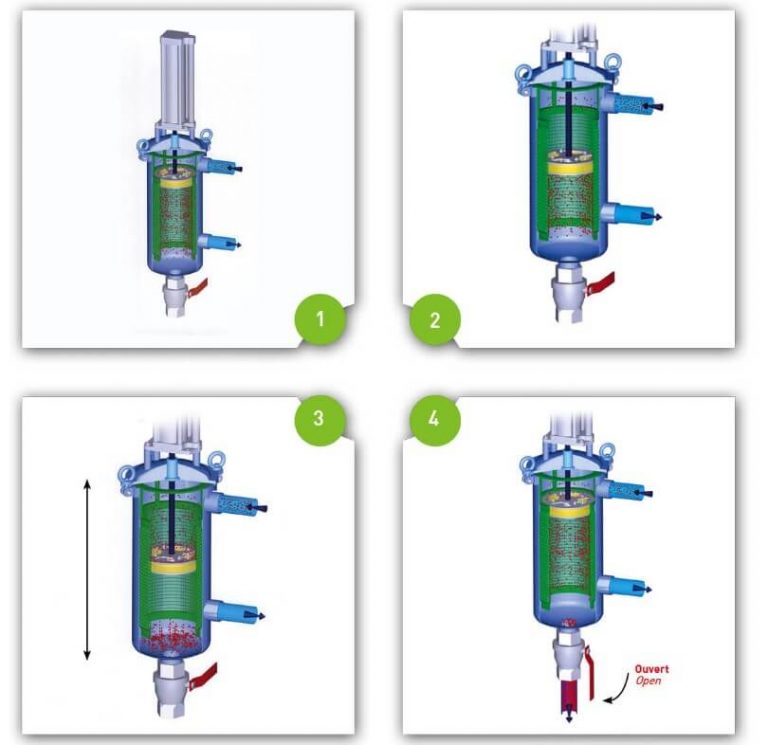

Operation of the mechanically cleaned filter

- The product to be filtered enters from the top of the mechanically cleaned filter. The fluid passes through the filter element, depositing unwanted impurities on the surface of the filter screen. The clean liquid passes through the filter screen and exits through the bottom outlet.

- The residues retained by the filter element are then removed by an automatic scraper that sweeps and scrapes the inner surface in a vertical back and forth motion.

- The combined action of the scraper and the flow directs the residue to the lower chamber of the mechanically cleaned filter.

- The impurities collected are removed by periodic flushing using a purge valve. This operation can be performed without stopping the filtration process.

Do you have a filtration inquiry ?

The advantages of the automatic self-cleaning filter

The PLM automatic self-cleaning filter has many advantages and applications in industrial processes for the filtration of viscous liquids. Among the strong points of the filter, one can quote a continuous filtration without the need for consumables like filter bags or filter cartridges, in a perfectly closed and clean environment, as well as automatic management of the residues.

The PLM automatic self-cleaning filter can be operated at different levels of automation, and because of its French manufacturing and design, it is particularly resistant, reliable and can be “customized” on-demand.

Continuous filtration

The PLM mechanically cleaned filter in stainless steel is equipped with a self-cleaning system that continuously removes the residues left on the filter screen. With this system, there is no need to slow down or interrupt the filtration process during cleaning.

Full closed and clean filter

The PLM self-cleaning filter in stainless steel is a fully enclosed filtration system. Unlike filter housings with bag or cartridge filters, it does not require to be opened at the end of the filtration cycle. There is no contact of the product to be filtered with the outside, avoiding the problem of contamination or external pollution that can occur when replacing the filter cartridge or filter bag.

Low maintenance

The PLM stainless steel filter vessel is durable and resistant, the stainless-steel filter screen is virtually indestructible and the high-density plastic scraper ensures simple and efficient operation. This self-cleaning wiper filter has few moving parts and few spare parts, reducing its maintenance and operating costs.

A true self-cleaning filter

The filtration surface is cleaned regularly and automatically. The wiper continuously scrapes the surface of the filter screen to maintain a constant and even flow rate, ensuring that the automatic self-cleaning filter stays clean over the entire filtration cycle. Product losses are minimal because only impurities are evacuated during the purging process.

A true automatic filter

The PLM automatic self-cleaning filter can be programmed with different levels of automation, from simple manual control to integration and supervision. The pneumatic electrical boxes operate with timer settings or with pressure sensors installed on the filter.

Pressure sensors are used to trigger the scraper by continuously monitoring the differential pressure upstream / downstream and to limit the number of scrapings when working with abrasive products, for example. The K2TEC team will be pleased to share its expertise in the choice of automation that best suits your needs.

French design and manufacturing

The PLM automatic filter has been manufactured with French quality.

K2TEC incorporates all your specifications and needs and transfers them to its engineering and design experts who can offer standard solutions and also integrate the automatic scraper filter into your process. All of our products, filter components and sub-assemblies comply with the quality standards of the European Community and, as an additional benefit to our customers, it is possible to order all the documents and material certificates on request.

The filters are manufactured following the Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 concerning machinery.

Options for the mechanically cleaned filter

The mechanically cleaned filter can be manufactured according to your standards and can also benefit from many customization options such as filtration rating, type of inlet and outlet, finishing level, automation level, and more.

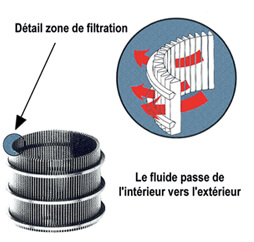

Filtre screen

The filter screen consists of a trapezoidal wire, which has been calibrated, coiled and welded. Its geometry prevents any deep clogging. The screen can be made of 304 or 316 L stainless steel. The standard filtration ratings are: 25 µm, 50 µm, 75 µm, 100 µm, 150 µm, 180 µm, 230 µm, 300, µm, 380 µm, 500µm, 610 µm, 800 µm and 1000 µm. All filtration ratings are available on demand.

Finishing

The filters in the PLM range are all manufactured in stainless steel with different possible finishes: passivated, bead-blasted, electro-polished or manually polished, depending on the process requirements.

ATEX certification

On request, K2TEC can manufacture the self-cleaning filter with ATEX certification II 2G II c T4 for operation in hazardous areas.

PLC control panel

The PLC control panel is electro pneumatic and can control the cylinder, the drain valve, a pump, etc. Different levels of automation of the automatic self-cleaning filter are possible: manual control, pneumatic control box, electro-pneumatic control box, pressure sensors to trigger the scrapping by monitoring the differential pressure.

Removable bottom

The removable bottom facilitates cleaning the filter, allowing full access to the stainless-steel filter housing.

Inlet & outlet

K2TEC offers several types of inlets and outlets such as male or female threaded fittings, tri-clamps, flanges, cam locks, SMS unions, half couplings, etc.

Design and manufacturing: K2TEC engineering and design department

K2TEC has an engineering and design department specialized in offering tailor-made solutions for all kinds of industrial applications. Based on our standard products, we can “customize” our entire range of filtration systems and filtering machines to suit the requirements of your process.

Applications of the PLM automatic self cleaning filter

The PLM industrial self-cleaning filter is ideal for many industries thanks to its high durability, simplicity and reliability. Wherever filter bags clog and tear or viscosity is too high for other industrial filtration systems, the PLM industrial self-cleaning filter is the solution.

Some of its most popular applications are industrial paint filtration for both solvent-based and water-based products, as well as paint filtration for the automotive industry and metallic supports.

The PLM industrial self-cleaning filter is also used in chemical and pharmaceutical processes and the food industry for the filtration of pastries, sauces, surimi, jams, chocolate, caramel, and more.

EVO Self cleaning strainer

Self cleaning strainer with scraper and twin actuator design for the filtration of highly viscous, abrasive or sticky liquids.

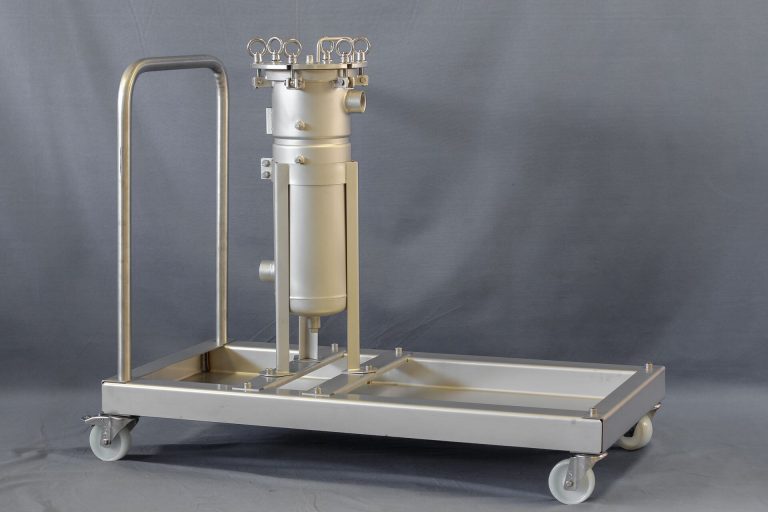

Filter skids

Filter skids and mobile industrial filtration systems for bag filter housings and automatic self-cleaning filters.

KBF Bag filter housings

Range of stainless steel bag filter housings. K2TEC specializes in filter vessels and filter bags, providing the best solution for liquid-solid separation.