K2 Tec

Home > Filter elements > Vacuum filter belt > Wear belts for vacuum boxes

Wear belts for belt filter vacuum boxes

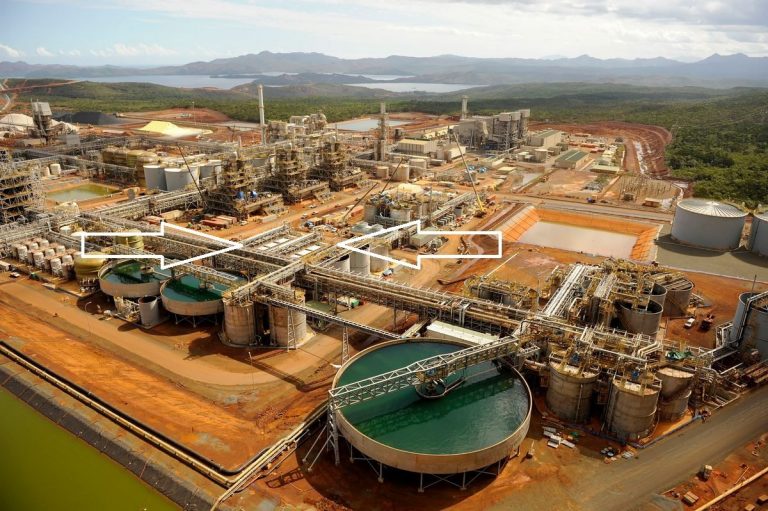

The vacuum belt filters have been used for many years in different industrial process industries such as mining, pharmaceutical, chemical and food.

Since 1995, K2TEC has developed, first in collaboration with Filtres Philippe and later with many customers, a full range of wear belts for vacuum boxes.

These belts can be used on all vacuum belt filters using the vacuum box technology such as RPA – Filtres Philippe, Delkor, FL Smith…

The wear belts undergo all the effort due to the vacuum and allow the sealing between the fixed part (sliding strips) and the rotating

part (rubber band).

- Wear resistance

- High tensile strenght

- Value for money

- Materials: polypropylene and polyester

- Chemical compatibility

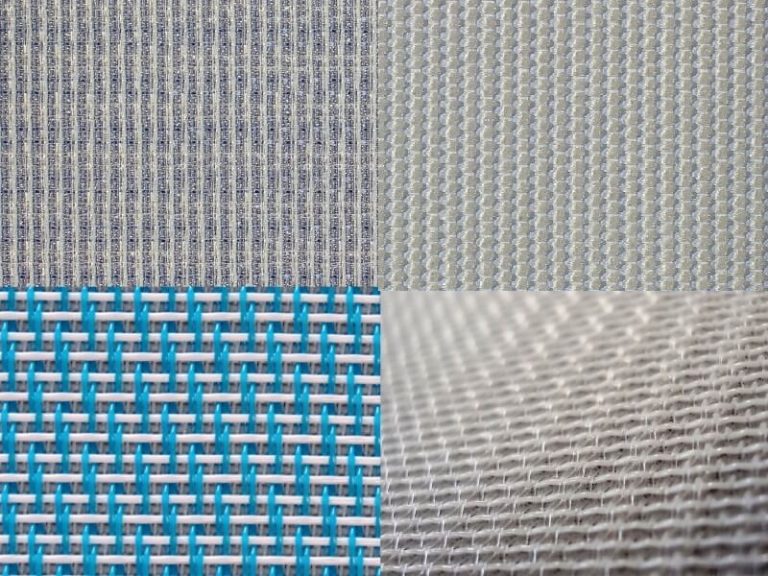

Manufacuring of the wear belts for vacuum boxes

Numerous tests were necessary to produce belts vacuum boxes with 100% satisfaction. Today K2TEC has the experience and know-how to produce perfect belts.

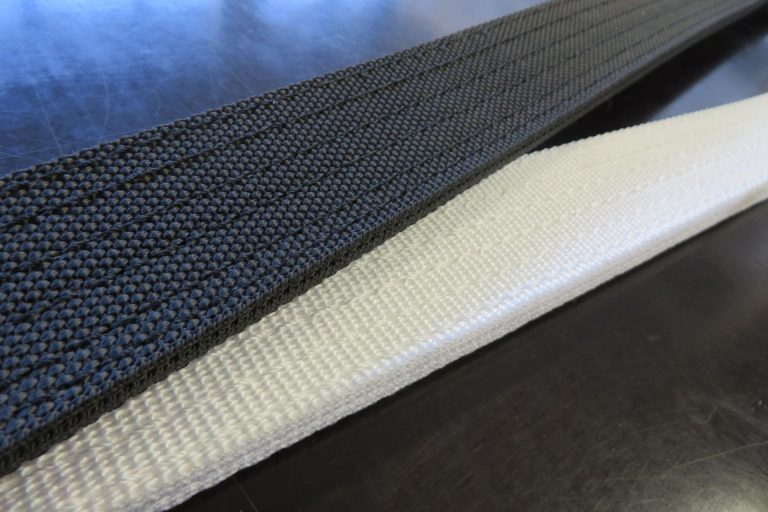

Raw materials are carefully selected and of the highest quality. The belts are available in several widths, the most common are 28mm, 38mm and 50mm but all widths are possible.

The machinery settings are optimised according to the length, which can range from a few metres to more than 90 m with a tolerance of a few mm. Thicknesses range from 3 to 12 mm. All dimensions can be modified and especially adapted according to the filter models and their fields of use.

The belts benefit from a so-called “endless” assembly method. The endless assembly guarantees the absence of overthickness along the length of the belt. This assembly method ensures that the belts have the same mechanical strength along their entire length.

The belts can be made of 100% Polypropylene, 100% Polyester (or a combination of both materials) and are therefore compatible with most chemical environments.

Where are the wear belts for vacuum boxes ?

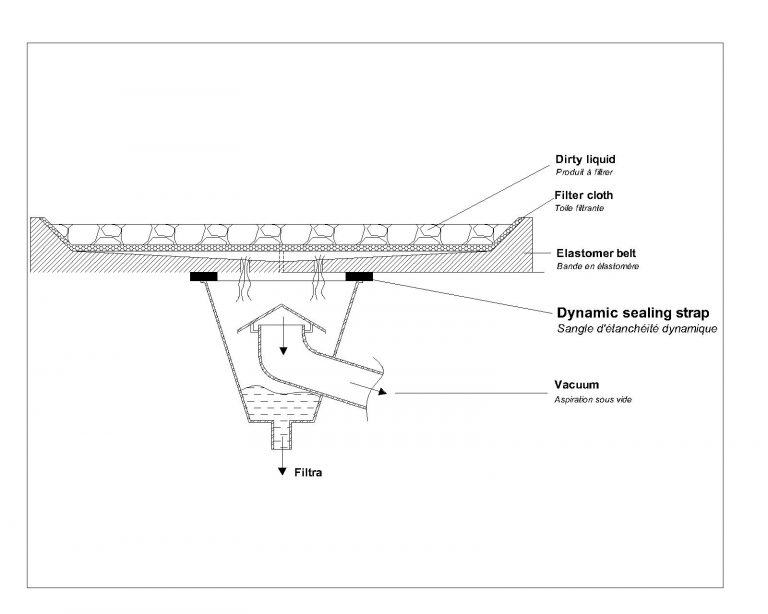

We can separate this system into different subsets:

The filter cloth in contact with the product : it acts as the filter medium. The product is uniformly deposited on its surface and the filter cloth ensures the liquid / solid separation.

The elastomer (or synthetic) support band : this band is under the filter cloth; it is grooved and holed so that the suction is uniform on the filter cloth. This flexible support band also provides the drive in rotation of the filter cloth and the product to be filtered.

The vacuum boxes: these are the interface between the vacuuming and the filtra evacuation; these are strategic elements of the system. They work much like separators pots for the extraction of air that creates a vacuum under the elastomer band and the filter cloth. They also collect the filtra.

The wear belts: they provide dynamic sealing between the fixed part (sliding strips) and the rotating part (rubber band). They were originally made of elastomer which has good qualities for sealing but poor resistance to abrasion and chemical attack that some vacuum belts filters have to undergo.

Examples of vacuum belt filters using K2TEC wear and sealing belts

These other filters may interest you :

Coolant filter belts

Manufacturer of industrial filter belts for coolants, oils and emulsions in the mechanical industry. 30 years of experience in filtration.

Filter cloths

Nylon, polyester, polypropylene, PTFE… filter cloth for industrial filtration, and for the manufacture of custom-made filter elements.

Vacuum filter belt

Manufacturer of filters belt for vacuum filters, in the chemical, mineral, pharmaceutical and mechanical industries.