K2TEC provides filtration solutions for the chemicals and polymers

Home > Applications > Chemicals & Polymers

Industrial Liquid filtration for the chemical industry

The chemical industry is a major contributor to the economy in France, Europe (France is the 2nd European producer) and worldwide (7th world producer). This industry regroups activities as varied as the manufacture of polymers, paints, the pharmaceutical industry, and petrochemicals. French production of chemical products is mainly exported, representing a growth driver.

Liquid industrial filtration for the chemical industry is a crucial step in many processes:

Safety filtration before packaging (elimination of undesirable particles).

Closed cycle filtration (cleaning solutions, solvents).

Process filtration (removal of poorly dispersed loads, dry particles, etc.).

Filtration before waste treatment (standardisation of solid loads in liquids before treatment).

Chemical industry specialists have specific needs depending on their sector of activity (basic chemistry, fine chemistry, green chemistry, etc.). K2TEC offers products that comply with REACH and also CE and FDA standards for food contact.

Do you have a filtration inquiry ?

When the viscosity of the product exceeds 5000 cps, when the load becomes relatively high or when the environment is aggressive/dangerous, the automatic self-cleaning PLM filter is particularly suitable for this type of filtration of chemical or pharmaceutical liquids. This closed filtration system can be fully automatic and controlled either through a dedicated PLC or through centralized supervision.

Applications

- Filtration of gels

- Filtration of silicone

- Filtration of low or high viscosity coatings

- Filtration of hazardous products such as hydrochloric acid, sulphuric acid, nitric acid, hydrobromic acid, etc.

This automatic, self-cleaning filter can also be used on all types of solvents, thanks to an ATEX certification.

The KBF stainless steel bag filter housing is a product commonly used in the chemical industry for the solid-liquid separation of all types of products. It is difficult to make an exhaustive list of products and applications for the stainless steel bag filter vessel. Nevertheless, the bag filter housing is often found in synthetic chemistry, petrochemistry, polymers, paints, and oleochemistry.

Main features:

- Robust

- Easy-to-use

- Great versatility: capacity to adapt to both, filtration or waste processes, in the chemical industry.

Filtration can be performed by filter bags with a filtration rate between 0.5 microns and 2000 microns, but also by a simple basket for coarser filtration processes such as pre-filtration.

To give our customers in the chemical industry a complete the service and a full range of coherent industrial filtration solutions, K2TEC also offers filter media as well as custom filter elements to meet all the requirements of the chemical and pharmaceutical fields.

K2TEC filter bags are available in several materials and configurations compatible with the processes used in chemistry.

These filter bags can be made of polyamide (nylon), polyester or polypropylene for standard applications. For more aggressive chemistries we also have PVDF or PTFE (Teflon) filter bags.

Filter bags are available either as single-use filter media or as reusable filter media, according to the chemical filtration process.

K2TEC has a variety of supports and o-rings. These can be simple galvanized steel o-rings or 304 / 316 stainless steel o-rings or polypropylene or polyester o-rings depending on the material used for the filter media.

The configurations of shapes, seams, welds, etc, comply with industrial standards and at K2TEC we have no problem manufacturing custom filter bags.

The gravity belt filter is used in the chemical industry for numerous solid-liquid separation processes. Whether it is a vacuum belt filter or a press belt filter, it uses a filter media in the form of a filter belt.

This filter belt can be made of various materials such as polyamide (nylon), polyester, polypropylene, etc., or even PVDF, PTFE (Teflon) or PEEK.

These filter belts for the chemical industry are always carefully chosen according to their chemical compatibility.

Filtration rates can range from a few microns to several hundred microns.

Widths vary from a few centimeters to several meters. The lengths are adapted to the filter used. K2TEC can easily manufacture heavy filter belts longer than 50m.

For filter belts, K2TEC has developed a range of high-performance and easy-to-install closures, including a patented product.

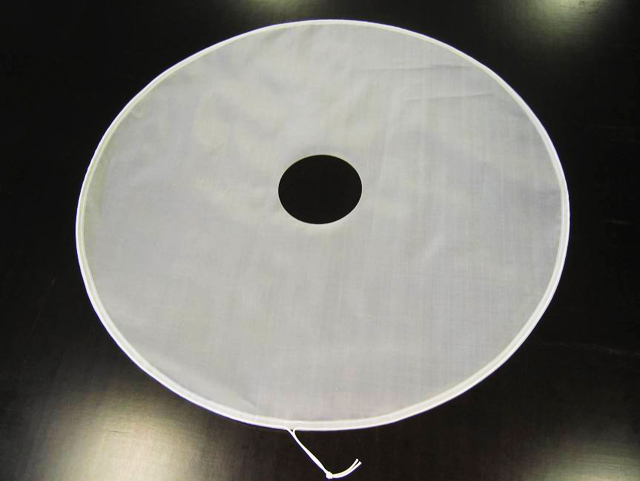

K2TEC has developed a range of filter fabrics ideal for Nutsch filters or leaf filters in the chemical and pharmaceutical industry. These filter media can be reusable or single-use.

The filtration rate of filter media is wide, it ranges between less than 1 micron and 4000 microns. K2TEC also has a variety of materials and weaves for chemical applications that are compatible with the majority of chemical and pharmaceutical processes.